特殊钢大棒材生产线

信息来源:本站浏览次数:18065

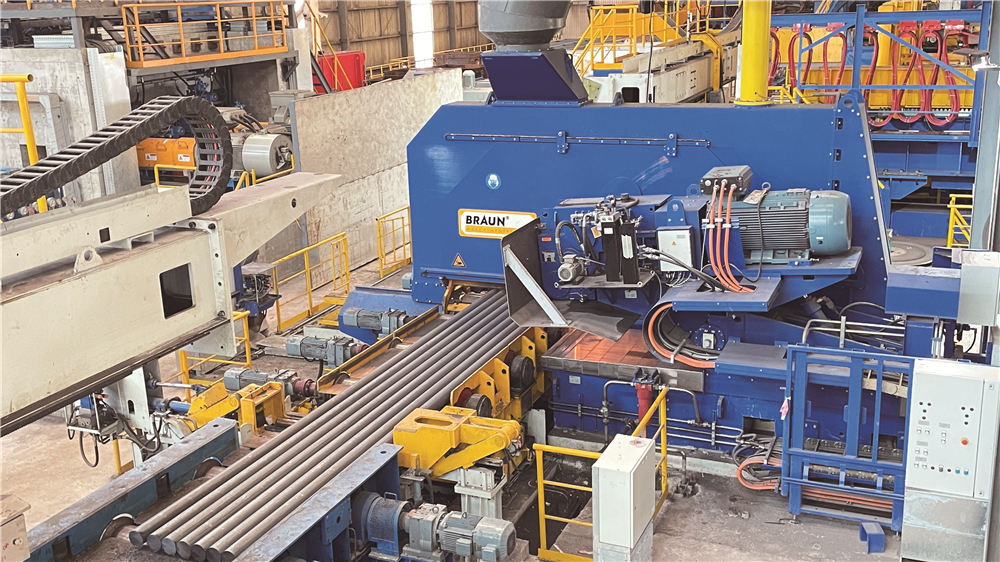

特殊钢大棒材生产线总体工艺由意大利达涅利公司设计。加热炉、开坯机、钢坯火焰清理机、连轧机、飞剪、kocks减定径轧机、组合锯、砂轮锯等关键核心设备和部分控制系统从法国斯坦因公司、意大利达涅利公司、美国L-TEC公司、德国kocks公司以及奥地利布朗公司引进;该生产线采用在线测径技术、无损探伤技术、控轧控冷技术、在线火焰清理技术、热装热送技术,ø50mm~ø160mm配备德国KOCKS减定径轧机,可实现自由尺寸轧制。产品规格:圆钢ø50mm~ø300mm;方钢100mmx100mm~180mmx180mm;轧制用坯150mmx150mm~360mmx360mm。着力打造以轴承钢、齿轮钢、弹簧钢、合金结构钢、优质碳素结构钢、非调质钢、高压锅炉管钢、锚链钢等产品为主的特殊钢生产基地,覆盖汽车及工程机械、石油化工、风力发电、铁路及轨道交通等行业。该生产线生产灵活,适应性强,产品精度高,组织性能稳定,锯切质量高,技术装备、产品质量及自动化水平均达到了国际先进水平。

主控室

意大利达涅利开坯机

连轧机组

美国 L-TEC 火焰清理机

德国 KOCKS 轧机

奥地利布朗锯