特殊钢大圆坯连铸机生产线

信息来源:本站浏览次数:2942

特殊钢大圆坯连铸机采用了达涅利设计制作建设的两机两流连铸机核心设备技术,可生产ø500mm~ø1300mm大断面连铸圆坯,该生产线应用了全流程保护浇注、中间包电磁感应加热、自动开浇、涡流液面自动控制、自动加保护渣机器人、铸流电搅、铸坯加热、激光定尺、自动喷号机器人等国际领先技术,是集工艺先进性和智能化为一体的世界一流连铸生产线。

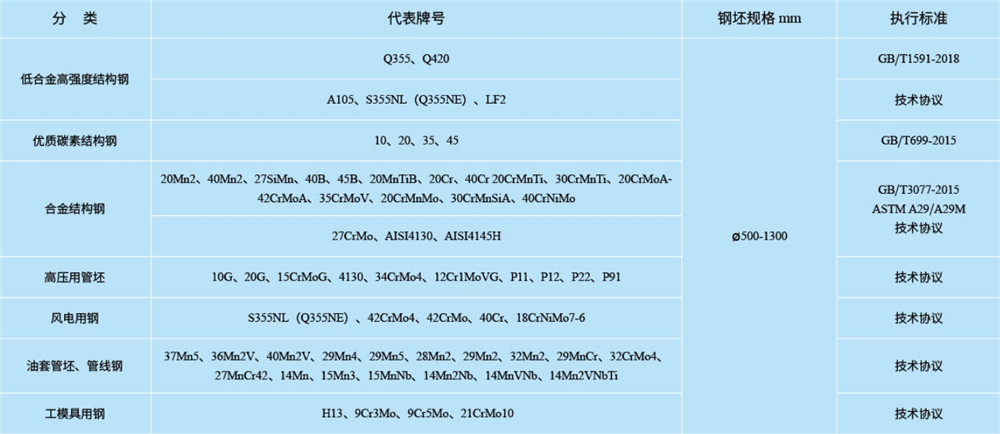

年设计产能30万吨,产品主要面向大型海洋风电、大规格石油油服阀体等新能源领域,生产钢种涵盖风电环件用钢、高压锅炉管用钢、油气管坯用钢、油气锻件用钢、工程机械用钢、工模具等高端制造用钢、能源用钢、工业用轴承等。